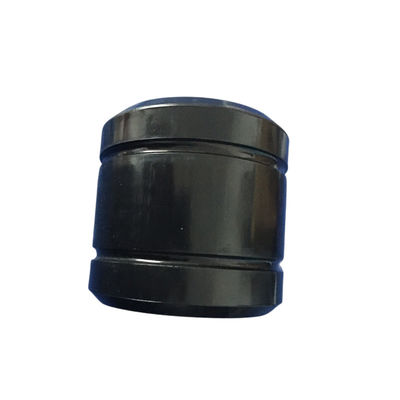

High-Pressure Bridge Plug Elements HNBR and FKM Sealing Solutions

Product Introduction

The High-Pressure Bridge Plug Elements are critical components in downhole zonal isolation, designed to provide a secure and reliable seal in the most demanding wellbore environments. Whether used in permanent or retrievable bridge plugs, these elements are engineered to withstand extreme differential pressures and aggressive chemical exposure. By utilizing high-performance elastomers like HNBR and FKM, our sealing elements ensure a gas-tight seal that facilitates fracturing, acidizing, and well abandonment operations. These elements are precision-molded to expand uniformly under mechanical or hydraulic force, ensuring complete contact with the casing wall.

Material Properties

We specialize in two high-tier elastomer materials to ensure success in hostile downhole conditions:

HNBR Hydrogenated Nitrile Butadiene Rubber: Known for its exceptional physical strength and mechanical toughness. HNBR offers excellent resistance to abrasion, extrusion, and tearing. It is highly effective in environments containing Hydrogen Sulfide (H2S) and Carbon Dioxide (CO2) while maintaining its elasticity under high-pressure cycles.

FKM Fluorocarbon: The premier choice for extreme thermal stability. FKM is highly resistant to chemical attack from various wellbore fluids, including aromatics and aggressive acids. It is the gold standard for high-temperature and sour gas (H2S) applications where other elastomers might soften or lose sealing integrity.

Material Comparison: FKM vs HNBR

While both materials are designed for high-performance sealing, they serve different primary functions:

Mechanical Durability: HNBR is significantly tougher than FKM. It resists tearing and abrasion better, making it ideal for operations where the plug might be subjected to significant mechanical stress or high-velocity fluid movement.

Thermal Resistance: FKM can withstand much higher continuous temperatures (up to 200C) compared to HNBR (up to 160C). For ultra-deep or high-temperature reservoirs, FKM is the necessary choice.

Chemical Resistance: FKM offers a broader range of chemical compatibility, especially with aggressive completion fluids and aromatics. HNBR is excellent for H2S and CO2 but may be more susceptible to certain chemical solvents than FKM.

Low Temperature: HNBR typically maintains better flexibility in colder surface temperatures or during initial deployment compared to FKM.

Application

Application environment: oil, gas, gas condensate

Shanghai Qinuo manufactures a wide range of Packer Cups and replacement Packer Cups for the leading Packer Cup manufactures. These Packer Cups are developed to perform in varying well conditions and provide maximum durability and sealability in the toughest of oilfield conditions.

We manufacture both Wire Skeleton / Wire Mesh / Wire Frame Packer Cups and Rubber Packer Cups without any mesh.

Our Packer Cups are available in various sizes right from a 1-1/4″ tubing through a 7″ casing and more. Specific sizes / designs can be developed based on your requirements.

| Operating Pressure |

35 MPa |

| Environment |

oil, gas, gas condensate |

| Available Material |

FKM, , HNBR and nitrile rubber |

Other relative rubber products:

Our products are widely used at all kinds of cars, machinery, home appliance, electronic products, electric appliance, stationery, computers, oil equipment, and hardware spare parts.

We also can provide oilfield rubber swab cup

- The TA swab cup is a medium-duty, all-rubber variable lip cup that offers greater flexibility under lighter loads.

- The MV swab cup is a light-duty, all-rubber cup especially effective in fluid with a high ratio of suspended sand. It has multiple flexible, upturned lips that easily.

- The V swab cup is a ring-type, single-lip, flexible, all-rubber cup molded on a steel bushing. It is ideal for lifting sand-laden fluids and for light-load swabbing. It is a single version of the MV swab cup.

- The TUF swab cup is a flexible, synthetic rubber cup with spring steel reinforcing wires for heavy loads but is flexible enough for light or medium loads.

- The UF swab cup is an all-purpose, synthetic rubber cup containing strong, flexible spring steel reinforcing wires.

- The J swab cup is a durable, heavy-duty cup with a long, flexible lip and strong steel reinforcing wires which provide a good upstroke seal for lifting heavy loads.

- The GW swab cup is a heavy, flexible, single-lip cup reinforced by spring steel wire. The oversized lip creates a good upstroke seal.

Moulded Rubber Products

Rubber Bonded with Metal Products

Extruded Rubber Products

Packing and shipping

1: Express: S.F. ,DHL,UPS, TNT, FedEx ect, for urgent and small order.

2: Air shipment: air port to air port , or air port to door.

3: Sea shipment: suitable for bulk goods. it will takes more longer time than air shipment.

Our company

Shanghai Qinuo Industry Co. Ltd was established in 2003, is a new and high-tech enterprise integrating R&D, production and sales. Since its inception, we adhering to the "Quality for Survival, Innovation Competes For Development " concept, continuous development and innovation, we won a good reputation at home and abroad.

Our company provides professional plastic parts, rubber parts and maching parts design and production services, products mainly used in automobiles, household appliances, machinery equipment and oil industry and other fields. We have a professional production and sales team, "High-Quality, High Professionalism, High Efficiency" are the principles of doing things.

We have two factories, more than 30 injection molding machines, molding machines and CNC lathes. Our company is located in Pudong New Area, Shanghai. Elegant environment, convenient transportation, Only need 30 minutes from our company to Pudong Airport.

We adopt comprehensive quality management system, all components passed ROHS certification, our products are mainly exported to the United States, Canada, Britain, Germany, Finland, New Zealand, Australia and other countries and regions.

FAQ

Question: Why do many bridge plugs use a three-piece element design?

Answer: A three-piece design typically consists of a softer center element for primary sealing and harder end elements to act as anti-extrusion barriers. This configuration allows the element stack to seal against imperfect casing walls while resisting extrusion under high differential pressures.

Question: Can these elements be used in sour gas wells?

Answer: Yes, both HNBR and FKM are specifically chosen for their resistance to H2S. HNBR is excellent for high-pressure sour gas, while FKM is preferred if the sour gas environment is combined with temperatures exceeding 160C.

Question: What causes a bridge plug element to fail during setting?

Answer: Failure can occur due to improper sizing for the casing weight, debris in the wellbore preventing a uniform set, or using a material that cannot handle the wellbore temperature. Ensuring the elastomer hardness and material match the well profile is essential for a successful set.

Question: How does the expansion of the rubber occur?

Answer: The rubber element is compressed between the top and bottom cones of the bridge plug. As the tool is set, the axial compression forces the rubber to expand radially outward until it creates a high-interference seal against the casing ID.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!